Mitsubishi Fuso Truck and Bus Corporation (MFTBC) has announced plans to construct a test facility for recovering materials from used electric vehicle (EV) batteries. The facility, to be built at MFTBC’s Kawasaki Plant, is in partnership with battery recycling specialist True 2 Materials (T2M).

Starting in 2025, the companies intend to use this pilot plant to assess the reusability of anode, cathode, and electrolyte materials by battery cell manufacturers.

The project aims to address the anticipated increase in used EV batteries as demand for electric vehicles grows. MFTBC states it will “consider a business venture that recycles used batteries from EV trucks, such as its electric light-duty eCanter, and EV passenger cars, into compounds that can be directly used as high-quality blended materials in battery cells”.

Initial plans focus on commercialisation in Japan, with potential for overseas expansion in the future. MFTBC reports that its goal is to “maximise the value of battery materials by developing effective retreatment processes, and thereby reducing the total cost of EVs”.

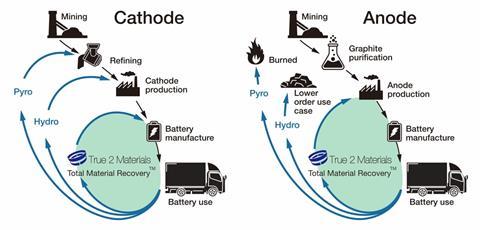

T2M has developed a technology called Total Material Recovery (TMR) for processing used and scrap batteries. The company claims this process “uses nano-level molecular techniques” and “allows recovery of up to 99.9% of all EV battery resources, a higher percentage than conventional methods”.

According to T2M, their process may also reduce CO2 emissions and other environmental impacts associated with battery disassembly. They suggest that “the cost of metal processing, which generally accounts for nearly 75% of the cost of the entire recycling process, will be significantly reduced.”

MFTBC describes this initiative as part of its Fuso eMobility Solutions framework to support customers’ transition to electric vehicles.