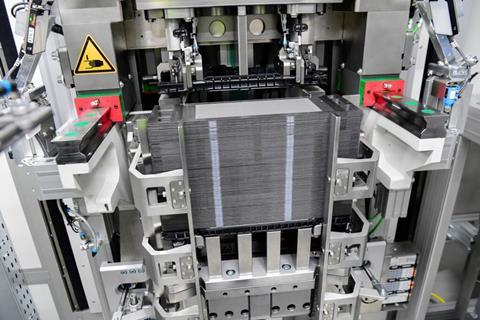

In a significant step towards sustainable heavy-duty transportation, French start-up Cellcentric has inaugurated a pilot production facility for fuel cell systems in Esslingen, Germany. This move brings the company closer to its goal of large-scale production of hydrogen fuel cells for long-haul trucks by the end of the decade.

The new 10,300m² facility will serve as a blueprint for future mass production, allowing Cellcentric to refine its manufacturing processes and prepare for full-scale operations. The company aims to produce fuel cell systems that achieve the best possible total cost of ownership in the competitive transportation industry.

Lars Johansson, Chief Commercial Officer of Cellcentric, stated: “Fuel cell technology is a well-proven solution for CO2-neutral long-distance heavy-duty transportation. However, it has not yet been produced on an industrial scale, which is precisely the key to achieving economies of scale.”

“The opening of our pilot production facility in Esslingen is not the end point of large-scale production, but rather the blueprint for the next step. In the coming years, we will continue to consistently drive forward the industrialisation and scaling of production of fuel cell systems at the Weilheim site,” added Johansson.

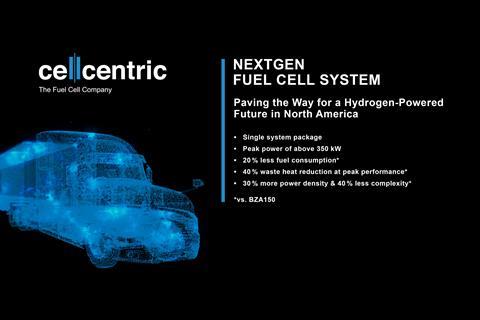

In May 2024, Cellcentric presented its smaller, more powerful and efficient NextGen fuel cell system for sustainable hydrogen-powered long-haul trucks for the first time at the ACT Expo in Las Vegas, USA.

In addition, with the BZA150 fuel cell generation, the company has a close to series production and already practical pilot product that has been successfully tested by truck manufacturers Daimler Truck and Volvo Group in demanding field tests. Series production of the NextGen fuel cell system is scheduled to begin at the end of the decade